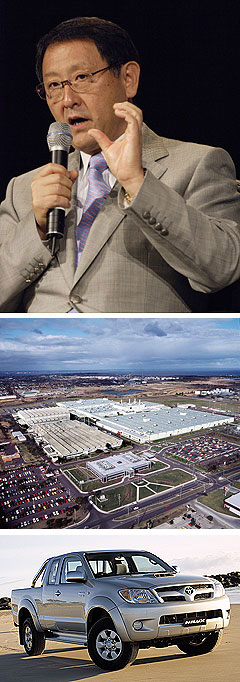

News - ToyotaToyota says quake cuts will drag onLeadership threat: Production cut-backs could cost Toyota its world number one position. Parts shortages set to keep brakes on Toyota’s Altona plant into June25 Apr 2011 PRODUCTION cuts at Toyota’s Australian car manufacturing plant at Altona in Victoria next month are likely to extend into June as parts shortages caused by the March earthquake and tsunami in Japan drag on. The company’s head office warned in Japan last week that Toyota global motor vehicle production might not return to pre-earthquake levels until November or December, although it hoped to ramp up supplies from July. Toyota’s Japanese plants are already running at only 50 per cent of their normal production rate, while plants in Thailand and the United States are down to just 30 per cent. As announced two weeks ago, the Australian plant will join the go-slow from next week, with a lack of parts halving production, to about 250 a day. Toyota Australia manager of public affairs and communication Glenn Campbell told GoAuto today a decision on local June production of Camry and Aurion would be made during May. “At this stage, the June outlook for the Altona plant looks very similar to May,” he said, meaning that the plant’s 3200 workers are likely to be asked to work half-day shifts into June for 75 per cent pay. Mr Campbell said the company was also keeping a close eye on stocks of imported vehicles. That situation has suddenly become more serious with the announcement that production at Toyota Motor Thailand’s three plants has been cut by 70 per cent until at least June 4. One of those plants supplies the company’s top-selling HiLux ute, which accounts for about 20 per cent of Toyota sales in Australia. “Toyota Motor Thailand produces many Toyota models, including HiLux, which are supplied to Australia,” Mr Campbell said. “We have just been advised on this production adjustment. Therefore, the direct impact on HiLux supply to Australia has not yet been determined. “We are monitoring (it) closely and will continue to provide updates to our dealers and our customers when we have more information.”  From top: Toyota president Akio Toyoda, Altona manufacturing plant and Toyota HiLux. From top: Toyota president Akio Toyoda, Altona manufacturing plant and Toyota HiLux.The earthquake disaster is forecast to slice Toyota total global production by 800,000 vehicles by the end of June, with the world’s number one motor vehicle manufacturer likely to have its worst annual sales volumes since 2009. Other companies such as Nissan – Japan’s second-biggest car-maker – are also running at severely reduced levels, with little prospect that production will pick up for at least two months. At a media conference in Japan on Friday, Toyota president Akio Toyoda apologised to customers for the “enormous delay” in delivery of vehicles. Our entire company is committed to solving the problems before us so that we can achieve production recovery even one day sooner,” Mr Toyoda said. Toyota said in a media statement that global production would ramp up “as soon as July in Japan and August in North America”, adding that the difference of a month between the two locations was due to shipping times for parts. But the company cautioned that all models might not get back to normal production until November or December. “Currently, manufacturing plants in Japan are working at 50 per cent of capacity due to parts availability, while those in North America are operating at 30 per cent of capacity because of the parts supply situation,” TMC said. In March, about 500 parts were in short supply because of damage to component factories, rolling electricity blackouts or transport disruption. “There are now approximately 150 parts affecting new-vehicle production, mainly electronic, rubber and paint-related,” the company said in its statement. Japanese newspaper Asahi Shimbun reported that one of the parts-makers crippled by the quake, semiconductor wafer producer Renasas Electronics Corp, would be out of action until June 15 and then only capable of five per cent capacity for the foreseeable future. The impact on Toyota production is set to put General Motors back in the box seat to reclaim world car sales leadership this year. Globally, Toyota gained the title of the world’s biggest auto-maker from GM in 2008 after the Detroit-based company stumbled in the GFC. Last year, GM recovered to the point where it fell just 30,000 units short of reclaiming the title from Toyota, selling 8.39 million vehicles to Toyota’s 8.42 million. Spurred by massive growth in China and success with new models such as the Cruze in North America, GM might have recaptured the title from Toyota anyway in 2011, especially after Toyota was battered by a series of vehicle safety recalls around the world in 2010. Unlike the Japanese companies, GM and fellow American manufacturer Ford have been largely unaffected by the parts shortages, enabling them to power ahead on a surge of renewed economic confidence in North America and elsewhere.  Read more |

Click to shareToyota articlesResearch Toyota Motor industry news |

Facebook Twitter Instagram