Make / Model Search

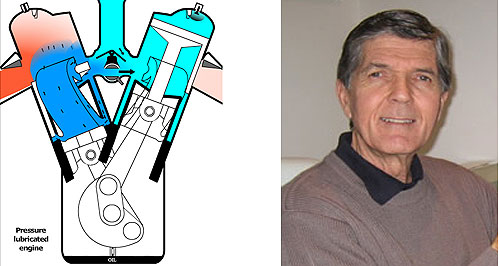

News - General News - TechnologyRadical two-stroke wins plauditsDifferent strokes: Basil van Rooyen and his Crankcase Independent Two Stroke (CITS) engine. ‘Clean’ two-stroke engine gets thumbs up at automotive engineering awards5 Oct 2012 By IAN PORTER RETIRED race driver and engineer Basil van Rooyen has received a special commendation from the Society of Automotive Engineers Australasia for his modern take on the two-stroke engine. The expatriate South African claims his patented direct-injected engine should meet tough Euro 6 emissions standards as a constant-speed onboard generator for an extended–range hybrid vehicle. He said it should also offer better emissions, smaller bulk and lower cost than the two-strokes that are found in the outboard motor and recreational vehicle market today. Mr van Rooyen rose to prominence in South Africa when he raced in the world championship South African grands prix in 1968 and 1969. Later he organised the South African GM dealer team and made 100 Vauxhall Firenzas fitted with Z28 Camaro 5.0-litre V8s. They dominated the domestic saloon car series. In 1977, Mr van Rooyen raced alongside Peter Brock in the Bill Patterson Racing Toranas, placing 4th in the Sandown 500 and failing to finish the Bathurst 1000 after his larger-than-life co-driver, the late Gerry Marshall, somehow pulled the driver’s seat out of the Torana’s floor. Mr van Rooyen moved to Sydney and has had a successful career as chief executive of a manufacturing venture. He was behind the HeeBeeGeeBee motorized head massager. Now 73 and “retired”, Mr van Rooyen has been working on his radical two-stroke engine for four years. He claims the new motor will eliminate the two-stroke’s traditional drawbacks of poor emissions and vibration and finally capitalise on the advantages it has over four-strokes, a high power to weight ratio and low production cost thanks to the elimination of the valve train. His new two-stroke does not need oil mixed with the fuel and he expects it will be clean enough to meet Euro 6 regulations as a constant-speed onboard generator. The two cylinders are placed close to each other, shortening the crank by 60 per cent and minimising vibration. There is a bit more manufacturing involved compared with a traditional two-stroke, although Mr van Rooyen claims this is offset by the unit’s smaller crankcase and crankshaft and the elimination of expensive needle roller bearings required in a standard two-stroke. The keys to the new engine’s low emissions lie in the adoption of “lower cylinders” or thimbles below the main pistons. These are fixed in place but allow a pushrod extender to pass through and propel the piston up and down, similar to the crosshead system found in large marine two-stroke diesels. The thimbles are below the inlet and exhaust ports in the cylinder walls. They stop the incoming air from flowing into the crankcase as the piston rises on the compression stroke. As the piston comes down, the air is then pushed through transfer ports in the cylinder wall and up into the combustion chamber, where fuel is injected and ignited. The corralling of the incoming charge by the top of the thimble, which stops it flowing into the crankcase, gives the engine its name – Crankcase Independent Two Stroke (CITS). An animation of the new engine can be seen at citsengine.webs.com. Like all two-strokes, CITS does away with the usual valve train found in a four-stroke, it still requires a one-way inlet value like any other two-stroke. Mr van Rooyen’s company, CITS Pty Ltd, has patented an optional pivoting inlet valve, which feeds air to each cylinder in turn, sealing the inlet tract on the other cylinder as it does so. Mr van Rooyen has also incorporated a by-pass valve, again an optional feature, which can replace the throttle as a power control and also lower pumping losses to improve economy. Neither of these valves is driven mechanically, the pivoting valve rocking from side to side to open and close each inlet tract while the by-pass valve is connected to the accelerator pedal. The exhaust port in the cylinder wall has an “exhaust valve” which drops down to partly close the exhaust port on the chamber wall, delaying the exhaust flow and thereby effectively giving the equivalent of variable valve timing, depending on how fast the CITS engine is spinning. Mr van Rooyen claims the use of unleaded petrol in a two-stroke means the engine will run as clean as a four stroke at constant speed. So far, Mr van Rooyen has shown his design to some leading engine developers from companies such as Ilmor, Cosworth and Orbital Engine Corporation and “none has rejected its potential”. Mr van Rooyen said his company,CITS Pty Ltd, was planning to raise $5 million in shareholder capital to pursue the development of the CITS engine.  Read more |

Click to shareGeneral News articlesResearch General News Motor industry news |

Facebook Twitter Instagram