Make / Model Search

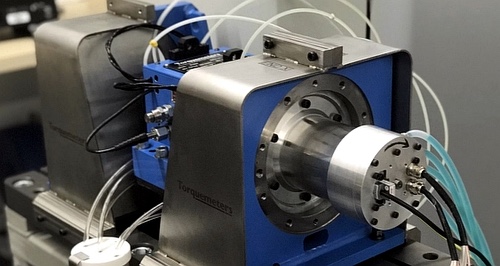

News - General News - Electric VehiclesAustralian team advances EV motor designSpin doctorate: The motor developed by University of NSW researchers may be a game-changer for electric propulsion and has many potential applications besides. University of NSW researchers come up with an EV motor packing improved power density13 Sep 2022 RESEARCHERS at the University of NSW have developed an electric vehicle motor design that promises to tick a lot of boxes in terms of size, cost of production, reliability, safety, power output and efficiency.

The potentially game-changing electric motor design is being developed by a team headed by associate professor Rukmi Dutta and Dr Guoyu Chu at UNSW’s School of Electrical Engineering and Telecommunications.

Said to have the potential to increase the range of electric vehicles, the prototype motor has has achieved speeds of 100,000rpm

It is an evolution of the Interior Permanent Magnet Synchronous Motor (IPMSM), a design predominantly used in traction drive of electric vehicles.

Maximum power and speed achieved by this novel motor have successfully exceeded and doubled the existing high-speed record of laminated IPMSMs (Interior Permanent Magnet Synchronous Motor), making it the world’s fastest IPMSM ever built with commercialised lamination materials.

The new IPMSM prototype motor was developed using the UNSW team’s own AI-assisted optimisation program which evaluated a series of designs for a range of different physical aspects – namely electrical, magnetic, mechanical and thermal.

Car-makers are likely viewing these Australian developments with keen interest and a view to adopting such a motor in production EVs but choices are already available to car-makers relating to what sort of electric traction motor can be utilised.

Ferrari and AMG for example have been looking for an electric edge sharp enough to satisfy “production” supercar customers, which means high-end axial flux electric motors fulfil their requirements.

Axial flux motors have the capability to deliver extra power out of a battery pack when a driver pushes the accelerator. It’s as simple as that. The motors are much smaller than predominantly used radial motors yet pack a more powerful punch.

By way of explanation, a conventional radial EV motor works by pushing hundreds, in some cases thousands of amps of electric current to copper coils. When these coils are energised, they become electromagnets with attractive and repulsive forces. The magnetic force created by a stationary stator surrounding a rotating rotor produces the torque that turns the wheels of the vehicle.

On the other hand, in axial motors, rather than have a rotor spin inside a stator, disc-shaped rotors spin alongside a central stator. This leads the flow of current – the flux – to travel axially through the machine, rather than radially out from the centre.

Since the motor generates torque at a bigger diameter, less material is needed thereby facilitating a smaller unit size.  Read more9th of September 2022  RS Q eTron E2 ready for assault on DakarQuick development times mean Audi is ready for Dakar desert race in 202318th of August 2022  Ferrari and AMG opt for axial flux EV motors'Elegant' axial flux motors will satisfy the performance demands of high-end supercar customers28th of June 2022  Lotus SUV on show at GoodwoodEmira lights up Goodwood with Eletre, Evija as Lotus moves quickly to all-EV line-up |

Click to shareGeneral News articlesResearch General News Motor industry news |

Facebook Twitter Instagram