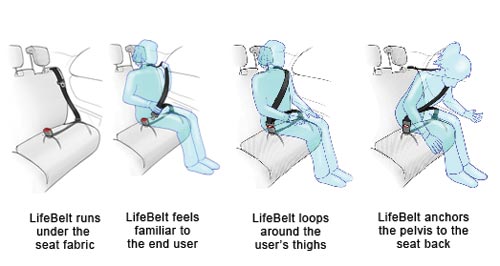

News - General NewsAdvanced seatbelt design wins top engineer’s awardLap-sash rethink: Lifebelt loops around the occupant’s thighs and anchors the pelvis to the seatback. Adelaide start-up, local suppliers and young guns recognised in SAE-A awards6 Sep 2010 By TERRY MARTIN THE belief of two Adelaide doctors – Lui Pisaniello and Marcel Stephan – that motor vehicle injuries could be reduced with a better seatbelt design has led to South Australian start-up company Lifebelt winning the gold award at the 13th annual Society of Automotive Engineers – Australasia (SAE-A) Automotive Engineering Excellence Awards. Also recognised were Futuris Automotive Interiors and Autoliv Australia, winning silver and bronze respectively, while Melbourne University research fellow Rahul Sharma took out the 2010 Young Engineer Award. First developed in 1999 and aided by a $70,000 AusIndustry COMET (Commercialising Emerging Technology) grant issued last year, Lifebelt is a universal integrated vehicle seatbelt similar in use and appearance to a conventional three-point belt, but which runs over the top of the legs and through the car seat, forming a loop around the legs. According to the SAE-A, the key to Lifebelt is the additional continuous webbing, which passes under the thighs to act as an anti-submarining device. It is also self-adjusting and able to fit all sizes of people, including children and pregnant women. The award was presented to Lifebelt chief executive Lino Fusco.  LEFT (from top to bottom): Lifebelt CEO Lino Fusco accepts the top award, watched by SAE-A president Patrick Ross SAE-A director Harry Watson presents the silver award to Jason Miller of Futuris SAE-A director Tim Car presents the bronze award to Autoliv’s Andrew Baldacchino RACV chief engineer Michael Case with 2010 SAE-A Young Engineer Award winner Rahul Sharma. LEFT (from top to bottom): Lifebelt CEO Lino Fusco accepts the top award, watched by SAE-A president Patrick Ross SAE-A director Harry Watson presents the silver award to Jason Miller of Futuris SAE-A director Tim Car presents the bronze award to Autoliv’s Andrew Baldacchino RACV chief engineer Michael Case with 2010 SAE-A Young Engineer Award winner Rahul Sharma.Taking silver, Futuris Automotive Interiors was recognised for its use of 3D knitted composite structures for lightweight automotive interior products. Working with AutoCRC, the CSIRO and Deakin University, Futuris has initially focused on vehicle seating, producing a composite seat ‘shell’ that combines a knitted reinforcing fibre (with a specific knit construction in the load paths of the structure) with thermoset resin. This is a cheaper, lighter (but still high-strength) design compared to traditional seating systems that are built around multi-piece, welded steel seat frames that are ‘trimmed’ with moulded foam and fabric. Autoliv Australia took bronze for its Transparent Engineering Process (TEP), which is described as “an advanced approach to product development and continuous improvement, targeting excellence in customer service, innovation, project management and personnel management”. According to the SAE-A, TEP is unique in that the process is based on lean manufacturing principles but applies them in an innovative and effective manner to the research, product design and development cycle. Meantime, Melbourne University’s Dr Rahul Sharma was recognised for his work on the mechanical engineering department’s ‘engine control program’, which is part of a multi-million dollar hydrogen-fuelled internal combustion engine project. The project is being run in collaboration with Ford Australia and the Victorian government, through an Energy Technology Innovation Strategy grant. Runner-up in the RACV-sponsored 2010 Young Engineer Award was Tom Woods, a researcher for the recently-released Automotive Australia 2020 project, which is a roadmap for the local automotive industry covering the next 10 years. SAE-A president Patrick Ross said at the awards ceremony that engineering innovation was “the key enabler to sustaining a revitalisation in the Australian automotive industry”. “The nation’s environmental and economic challenges can only be resolved by significantly improved products, services and processes underpinned by superior engineering,” he said. “The entries for the 2010 awards reflect the strength and innovation of automotive engineering in Australia. They are testament to an industry that has proven itself resilient in weathering a critical period while remaining focused on a brighter future. “The SAE-A Automotive Engineering Excellence Awards are important because they provide benchmarking and recognition opportunities among local peers. “They are also significant because they showcase our innovation on the competitive global stage.”  |

Click to shareGeneral News articlesResearch General News Motor industry news |

Facebook Twitter Instagram