Make / Model Search

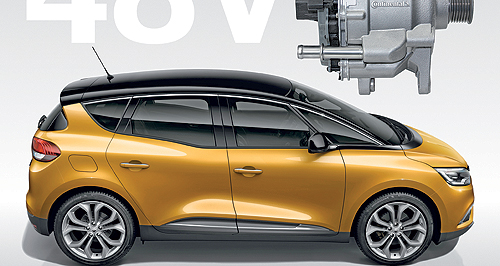

News - ContinentalContinental’s mild-hybrid tech cuts CO2 emissionsOne size fits all: Continental’s new mild-hybrid technology can be implemented on most existing powertrain set-ups to boost fuel efficiency and reduce CO2 emissions. Diesel more viable with Continental's new catalytic converter and mild-hybrid systemGallery Click to see larger images 27 Jun 2017 By IAN PORTER in HANOVER CONTINENTAL has developed, in conjunction with Renault, a new 48-volt mild-hybrid system which can be fitted to existing engines without the need for major re-engineering that can improve fuel efficiency and reduce carbon dioxide (CO2) emissions. Revealed at the Continental TechShow in Hanover ahead of a public debut at the Frankfurt motor show in September, the technology includes a starter-generator attached to the crankshaft by a belt and a lithium-ion battery to store regenerated energy. The new module not only starts the engine, it generates electricity on overrun and also works as a motor to help accelerate the vehicle. Renault worked with Continental on the system and will be the first to bring the technology to market when the new Scenic Hybrid Assist goes on sale later this year. There will also be a Hybrid Assist version of the new Grand Scenic. When demonstrating the system at the company’s Contidrom proving ground, Continental engineer Johannes Drechsel said the new technology could be very beneficial to oil-burning engines which generally emit higher levels of CO2. “Continental believes the diesel is not dead,” he said. The company is claiming significant gains in fuel consumption, emissions reduction and manufacturing costs. Tests have shown the system can reduce fuel consumption by 13 per cent under the New European Driving Cycle (NEDC) while Continental’s real-world testing has seen gains of as much as 21 per cent. Renault expects the addition of the mild-hybrid system to cut the Scenic’s combined cycle fuel consumption to 3.5 litres per 100km. This, in turn, helps reduce the Scenic’s emissions from 100 grams per kilometre to a class-leading 92g/km. Just as significant for a diesel-powered vehicle is the fact that the system helps make big cuts in emissions of nitrogen oxide (NOx). This is the result of the battery-assisted acceleration given by the new motor as the acceleration phase is when most NOx is produced. While there have been similar technologies in the past, Mr Drechsel said Continental’s decision to go with a 48-volt system delivers key advantages over the existing 300- to 400-volt systems seen so far. “Lift off the pedal and now the lithium-ion battery is recuperating,” Mr Drechsel said. “The energy is stored in the 48-volt battery, and 48 volts is the main point. “A standard hybrid system is 400 volts. We are below the 60-volt mark, in the low voltage area. “That means the system is cheap and easy to integrate, to update an existing vehicle with this system.” The combined starter and generator fits in the same space as a regular starter motor and is connected to the crankshaft by a belt drive that can transmit the unit’s 60Nm to the crankshaft. Continental says a belt drive could transmit as much as 150Nm. “This machine has much more torque than a 12-volt starter, boosting a very fast start in the idle/stop situation,” Mr Drechsel said. As the new unit will be in use for a significant portion of the driving cycle, Continental has made it water cooled by linking it into the engine’s cooling system. Tests have shown the Continental system starts a diesel engine in 0.2 of as a second, which Mr Drechsel says is “two times faster than the common starter-generator” and that “the faster it starts, the less energy is used to crank the engine”. The automotive technology company is expecting big things from its 48-volt approach to mild hybrids according to Continental head of hybrid vehicles Rudolf Stark, who said it offers similar advantages to all combustion engines, not just diesel. “In 2025 approximately one in five new vehicles will be equipped with 48-volt drive,” he said. “This includes all internal combustion engines, diesel, petrol or alternative fuels.” In addition, Continental also unveiled an electrically heated catalyst that further reduces pollutants by bringing the emissions-reducing unit up to temperature faster. Combined the mild hybrid system, this can reduce total NOx emissions by 60 per cent. The heated catalyst has a power rating of 3kW and is placed immediately upstream of the AdBlue injector in diesel-engined vehicles, and can also be used in petrol-powered cars to reduce cold-start emissions.  Read more22nd of June 2017  New approach to in-car audio from ContinentalContinental replaces speakers with acoustic panels to reduce weight, improve audio21st of June 2017  Continental reinvents the wheelNew lightweight Continental concept wheel improves brake rotor durability |

Click to shareContinental articlesMotor industry news |

Facebook Twitter Instagram