Make / Model Search

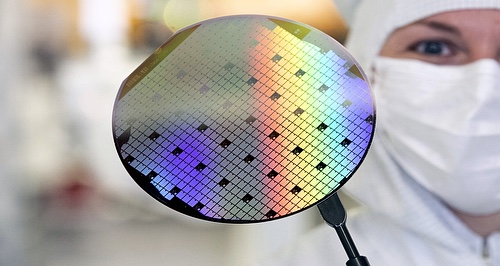

News - BoschBosch to manufacturer more chipsSemiconductor supplies to receive a much-needed boost from Bosch15 Jul 2022 THERE may be light at the end of the tunnel for the world’s microprocessor shortage with Bosch announcing plans this week to invest more than $A4 billion in its considerably growing semiconductor business by 2026.

According to Automotive News Europe (ANE), the investment will address a range of semiconductor needs across multiple industries and will include the addition of testing centres, research into new kinds of chips and, most importantly, new chip production capacity in Germany.

Over the past 18 months, a shortage of microchips has caused automakers around the world to cancel 13 million vehicles from production schedules.

Indeed, across almost all industries, the demand for semiconductors in 2020 and 2021 exceeded pre pandemic forecasts and this means automotive OEMs and Tier 1 suppliers are increasingly competing with companies in other industries for chips.

Global vehicle demand dropped dramatically during the first few months of the COIVD-19 pandemic and because of the microprocessor shortage, the manufacture of semiconductors, used in most electronic products was reduced or available stock was redirected away from the auto industry.

Despite COVID-19, unexpected spike in demand for new motor vehicles in the past 18 months has seen the production of semiconductors (chips) fall short of global demand and has emerged as a major problem for the auto industry.

Chips are the key component of a vehicle’s various electronic control units, and the constrained supply of chips has caused many manufacturers to cut or delay vehicle production or to delete certain features from vehicles.

The manufacturers of other products that use chips such as laptops and white goods are similarly affected by the shortage but not as severely as the automotive sector and they compete with car-makers for the same ‘available chip allocations’.

Russia’s invasion of Ukraine is a further complicating factor as Ukraine supplies 25 to 35 per cent of the world’s purified neon gas required for chip manufacture, and Russia supplies 25 to 30 per cent of palladium, a rare metal used for semiconductors.

If chip production could be magically and instantly increased, getting them to where they are needed is problematic due to the increased cost of air transport and reduced air transport capacity caused by the ongoing effects of the COVID-19 pandemic.

However, ANE reports the worrying news surrounding the Bosch announcement is that not all the investment is targeted at the automobile industry.

Bosch is the world's biggest auto parts supplier but also has a huge global portfolio of electronic products, ranging from coffee makers and toasters to home security systems, power tools, video surveillance products and air conditioning units.

“Microelectronics is the future and is vital to the success of all areas of Bosch business – we hold a master key to tomorrow’s mobility” Bosch Chairman Stefan Hartung said in a statement at Bosch’s Tech Day in Dresden, Germany this week.

“Europe can and must capitalise on its own strengths in the semiconductor industry. More than ever, the goal must be to produce chips for the specific needs of European industry.”

European government leaders hope to double Europe’s slice of global semiconductor production from 10 per cent now to 20 per cent by the end of the decade.

Additional production anywhere in the world is certain to help alleviate the global scramble for chips and other manufacturers would certainly be rising to the challenge given the financial rewards on offer.

“The supplier wants to solve not only its own yawning demand for more microchips, but also Europe’s. The investment will be made in response to the European Chips Act, with the European Union and German federal government providing some of the funding to foster investment to spur on the European microelectronics industry,” reported ANE.  Read more |

Click to shareBosch articlesMotor industry news |

Facebook Twitter Instagram