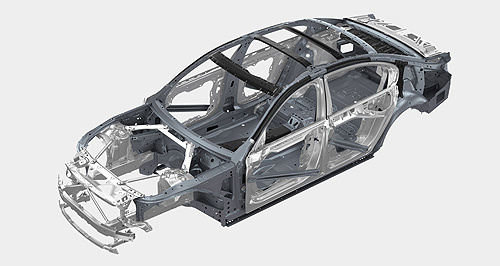

News - BMW - 7 Series7 Series to kick off carbon revolution at BMWPlastic fantastic: While the material and its manufacture are still a pricey proposition, BMW has added CFRP parts to important areas of the 7 Series chassis – and it won’t belong before the technology trickles down. Industrial scale carbon use for 7 Series will trickle down to BMWs to come11 Nov 2015 By TIM ROBSON THE use of carbon-fibre in cars is certainly nothing new, but BMW believes that its use in its 7 Series heralds a new era for the strong, light and expensive material. The company’s new luxury sedan has long held the position of technology leader for the rest of BMW's range, with a history of industry leading innovations trickling down to lower models. “Yes, it will come. Carbon-fibre is brilliant for weight saving, great for rigidity. It's just an expensive material to work with,” said BMW Group Australia head of product and market planning Shawn Ticehurst. “You pretty much can be assured a lot of this stuff will ultimately work its way further down the range.” The German company has used a version of carbon-fibre known as CFRP (carbon-fibre reinforced plastic) throughout the bodyshell of the new 7 Series, including in highly critical points such as the door sills and B-pillar, where safety standards are most onerous. A total of 25 CFRP pieces are used throughout the build of a 7 Series, all made in the Dingolfing plant in Germany from carbon sheets flown in from a plant near Seattle, Washington, which also supplies Boeing. Hollow long-form rods of CFRP are used to reinforce the roof and the door sills, while flat-formed pieces are installed at the B- and C-pillars, across the top of the windscreen, rear parcel shelf and along the transmission tunnel, among other places. Some pieces – like the door sill rods – are encased in steel tubes, while others are bonded to steel body parts to add stiffness and strength. The CFRP pieces are used as a part of a holistic approach, with high-strength steel and aluminium still making up the majority of the body structure. The company uses CFRP extensively for the i8 and i3, as well as for roof pieces for M3s and M4s. The i-cars are built around a modular CFRP occupant cell, while the carbon roofs are a limited-run item that are expensive to produce in quantity. The life-cycle of the new-gen 7 Series could run until about 2020, by which time BMW will have made up to a million CFRP pieces to cope with the worldwide demand for the car. A new code letter designation also points to a changing of the guard at BMW, with the 7 Series the first of a new ‘G’ series to be launched. “This is our first car that comes with a G-code. That really says a lot about it having new technology,” said Mr Ticehurst. “Future G-cars will then start to get this kind of technology. The more we work with (CFRP), the better we're going to get at bringing down the production times, bringing down the costs, all the rest of it. This is the first time we've been able to filter it down into a car that's not an i-car. “It's still expensive for now, but if we can roll it out more and more, then hopefully we'll hit that critical mass when you can filter it out into a bigger production run. It’s learning to work with the material as well you’ve got to get it out into real-world situations where it is going into a production car.” Much of BMW’s current model range is either new or coming up to mid-life cycle, and Mr Ticehurst says that the next mass roll-out of CFRP is down to the range renewal process. “It still depends on new model releases and all the rest of it, but yeah, you can pretty much be assured a lot of this stuff will ultimately work its way further down range,” he said. “So if you can get to work on 7 and master it, then we can make it viable to roll out into, let's say a 5 Series, or whatever may come next.”  Read more10th of November 2015  7 Series can be number one: BMWDespite big lead, BMW reckons it can overtake Merc S-Class with new 7 Series10th of November 2015  Driven: BMW aims for the top with 7 SeriesNew G-code 7 Series marks beginning of new era for BMW’s flagship sedan range |

Click to shareBMW articlesResearch BMW 7 Series pricing

Motor industry news |

Facebook Twitter Instagram