Make / Model Search

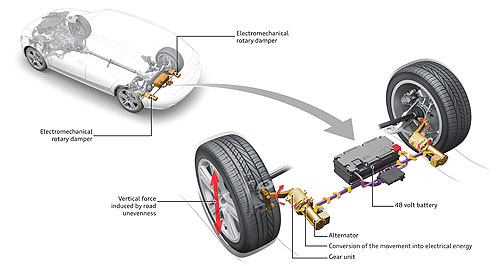

News - AudiDampers defunct with Audi eROTDamper on a stick: Instead of regular telescopic oil-filled dampers, Audi’s eROT system uses an electric motor connected to the suspension with a small lever. Revolutionary Audi innovation replaces conventional dampers with electric motorsGallery Click to see larger images 12 Aug 2016 AUDI is developing an electromechanical suspension damper that replaces the decades-old hydraulic type with a more efficient system that could make future production models more fuel efficient and spacious, while improving driving characteristics. Conventional oil-filled dampers convert the movement of a vehicle’s body into heat via the suspension system for a smoother ride, but Audi’s eROT system uses an electric motor in place of the telescopic damper bringing a number of advantage, the company says. Just as electric vehicle regenerative braking converts vehicle movement into electricity instead of generating wasted heat in the case of conventional disc brakes, the eROT damper uses the resistance of an alternator to cancel suspension oscillation. A lever arm is connected to the suspension where the lower joint of a hydraulic damper would usually bolt on, and transmits torque as the suspension moves to a gearbox, which turns the alternator. The electricity generated by the eROT motor can be fed into a battery to power the vehicle instead of dissipating as wasted heat energy produced by a hydraulic damper, but there are other benefits too. Where telescopic dampers are positioned vertically, housed in tall towers in the wheel arches, the motors are more compact and have a much lower profile. With less space occupied by the suspension system, a vehicle using the system could either be made smaller overall or offer more interior space. The eROT system also has another inherent design advantage that would allow variable suspension settings, with a simpler approach than the existing oil damper systems that use complex valve and mechanical technology. By altering how much electricity the motors produce, their resistance on the suspension can be adjusted. At peak regenerative efficiency, the motors exert the greatest resistance to the movement of the body for the firmest ride characteristics and minimal bodyroll, but by reducing the effect of eROT a softer setting can be created. Unlike existing damper settings which have mutually dependent compression and rebound strokes, the eROT system is more flexible and can be tuned with radically different strokes, including the classic rally car tune of rapid rebound but slow compression or the opposite setup of a circuit racer. The innovative system is still at an experimental stage but Audi says eROT is already proving itself and has the potential to reduce CO2 emissions by 3g per kilometre. Exact energy returns from the system vary on the type of road and driving style and range from three watts on a perfect surface to 613 watts on a poorly maintained surface, but Audi reports a figure of 100 to 150 watts on the average German road. Despite its relative simplicity, Audi says the technology is not something that can be simply slotted into models during a mid-life update, and that a more widespread vehicle integration is required, including the 48-volt electrical system that it is proliferating for its future electrified vehicles. When combined with the company’s next-generation hybrid technology, the new eROT dampers could cut fuel consumption up to 0.7 litres per 100km. Audi does not mention if the system was developed in conjunction with any partners or if it was an in-house project, but global suspension and drivetrain specialist ZF has been working on similar technology since 2013 at the latest. Unlike Audi’s interpretation, ZF’s GenShock uses the oil displaced in a hydraulic damper to drive an electric hydraulic pump in reverse to generate an electrical charge for the same end result. The difference with Audi’s system is that it cuts out the middle man of the hydraulics and sends torque to the generator mechanically and not through fluid pressure.  Read more |

Click to shareAudi articlesResearch Audi Motor industry news |

Facebook Twitter Instagram